This article is the third in a series exploring the methane opportunity: what it is, why it matters, and how OGCI Climate Investments is catalysing change.

Finding emissions is only half the story. We need the tools, both physical and digital, to mitigate them too.

Methane can escape at every stage of the oil and gas supply chain, from extraction to transportation and distribution. In the previous article in this series, we explored how aerial monitoring technologies are helping energy companies detect and locate methane leaks. But finding emissions is only half the story. Technology plays a critical a role in eliminating them too.

Around 70 million tonnes of methane leaks from oil and gas equipment each year, as hydrocarbons are extracted from the ground and pumped into pipes and tanks.[1] There are a number of ways to locate these leaks, including with new aerial instruments: satellites, planes, and drones. Historically, however, this equipment has been monitored manually – and so only periodically – by workers inspecting sites for leaks or damage. Catching methane leaks has therefore too often been a question of timing and chance.

Today, a number of companies are taking a different approach: continuous monitoring. Armed with new sensors and software, operators can now watch over their tanks, pipes and flares around the clock. This is both good for the world and good business too. Continuous, remote monitoring reduces the equipment failures that lead to methane emissions. It is also a commercial opportunity, reducing the incidence of costly safety issues and ensuring operators stop losing gas they could otherwise sell.

A new generation of businesses are leading the charge, and notable amongst them are two start-ups: Andium and Kelvin. Both outsiders to the industry, bringing an expertise in data more commonly found in Silicon Valley, their technology is transformative.

Today, a number of companies are taking a different approach: continuous monitoring. Armed with new software, operators can now watch over their tanks, pipes and flares around the clock.

Andium is a technology company based in New York. It fits well sites with internet of things (IoT) devices with optical and infrared sensors, using the latest artificial intelligence software to identify and intercept potential sources of methane emissions.

These tiny devices monitor operations constantly. The analysis, powered by the latest artificial intelligence and machine learning techniques, alerts operators to problems when they happen – while avoiding the false alarms common on older systems. In addition to reducing potential sources of methane emissions, the system lowers the frequency of manual well site visits required, lessening the risks and emissions of long drives out to remote well sites.

Kelvin, meanwhile, is a control systems company founded in 2013. Its software helps oil and gas operators – particularly engineers – to automate insights and repetitive manual processes into simple control applications. “A big part of our initiative is to empower engineers – to free them up to work on the things that are most important,” explains Peter Harding, Kelvin’s CEO. One of the benefits of this system control is that it can help to reduce methane emissions from venting.

While digital technology can point us in the right direction, it takes physical technology to stop methane emissions. Much of that technology is focused on two components in the fuel extraction process, which are particularly prone to venting methane: pneumatic devices and control valves.

Pneumatic devices are used by almost all oil and gas companies, critical to vital processes like regulating flowrate, pressure, and tank levels. However, these devices use gas pressure as a source of energy for actuation – and therefore often vent gas, primarily methane, directly into the atmosphere. They also wear out easily, and so are prone to further, accidental leaks too. Some estimates suggest that pneumatic devices represent up to one third of the sector’s methane emissions in the US alone.[2]

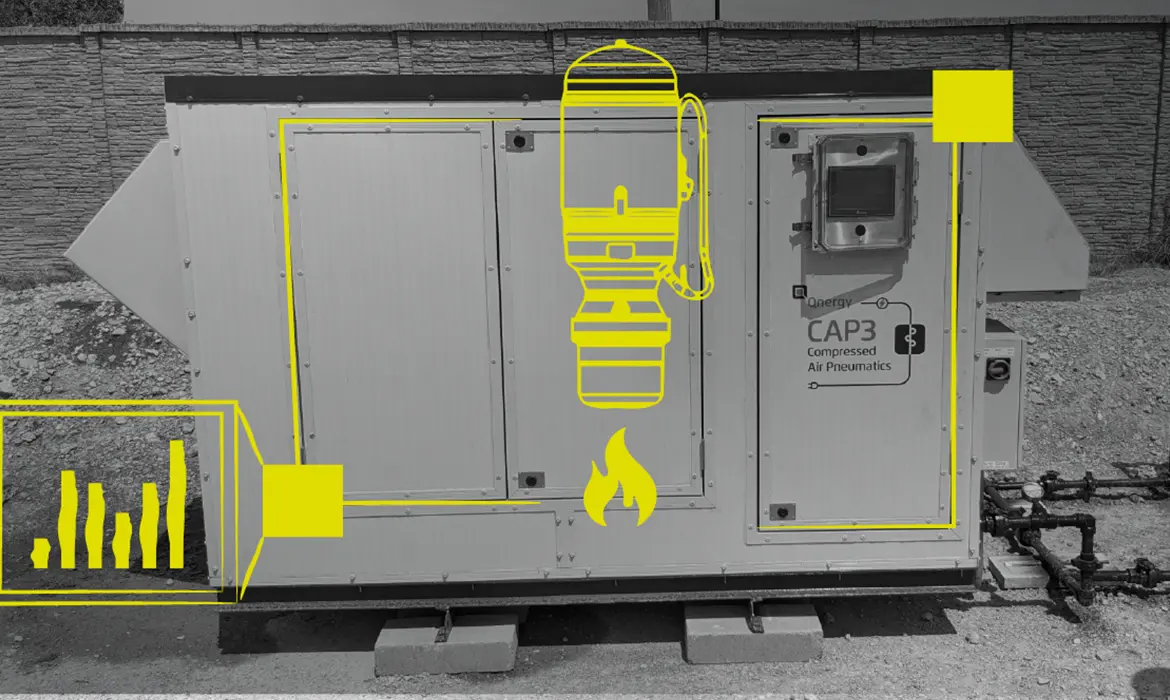

For many years, the only alternative to pneumatics were electric devices and controllers. In an industry that often operates far from power grids, in practice that amounts to no real alternative at all. But in 2013, a company called Qnergy developed an alternative, doing the work of a pneumatic device without venting methane.

In the summer of 2021 Hurricane Ida swept across Louisiana, “People had outages” remembers Ory Zik, Qnergy’s Chief Executive, “but our customers… didn’t even notice that there was a hurricane.”

Crucially, these remote compressed air generators demand little maintenance. NASA, no strangers to inhospitable locations, described Qnergy’s technology as “the most reliable heat engine ever invented.[3]” As testament to that fact, in the summer of 2021 Hurricane Ida swept across Louisiana and 300 of Qnergy’s devices. “People had outages,” remembers Ory Zik, Qnergy’s Chief Executive, “but our customers – from the perspective of power – didn’t even notice that there was a hurricane.”

Another critical part of the energy system is control valves. For liquids and gases to flow through the immense global network of tanks and pipelines, operators need adjustable valves that enable engineers to precisely control flow, level, pressure and temperature. Large, heavy and expensive, these valves are already a burden to operators. Worse still, they have a tendency to leak methane.

Clarke Valve, a Rhode Island-based company, has an answer. Founded in 2011, it patented a leak-proof control valve.

Clarke Valve helped Eni replace their valves at their oil field in Northern Italy.

Up to 80% smaller and 80% lighter, at a lower price than conventional valves, in third-party certification tests (to international valve standards) it leaked methane at a rate of 2 parts-per-million. Traditional valves leak at a rate of 500 parts-per-million.[4]

At the Trecate refinery, in Northern Italy, Clarke Valve has helped Eni replace its valves. A year after installation, Eni measured methane emissions at its site. For the first time ever, the instruments read zero. “At first, this was a little bit of a surprise – they wondered if the machine was calibrated properly,” remembers Clarke Valve Chief Executive, Kyle Daniels. But “they checked it, and came back, and it was still zero.”

Far from the oil fields, the risk of methane emissions continues as gas is piped into homes and businesses all over the world. Every time a worker breaks ground near a utility line, they risk digging directly into the complex lattice of pipes and cables underneath us.

The US Government estimates that a single pipeline rupture can release more than 1,000 tonnes of methane.[5]

Dozens of utilities in North America use Urbint to predict and prevent damages, reducing pipeline ruptures by 30% or more.

Urbint, a US-based technology company, has developed an AI-based technology to reduce the chance of striking a gas pipeline – which it estimates currently occurs around 85,000 times each year in America alone. Urbint identifies high-risk projects so that utility, energy, telco and infrastructure firms know when third parties are excavating a high-risk site. Today, dozens of utilities in North America use Urbint to predict and prevent damages, reducing pipeline ruptures by 30% or more.

Methane leaks are not one big challenge, but instead a plethora of small ones, with leaks emerging across the oil and gas process. Peter Harding, Chief Executive of Kelvin, believes we have no alternative but to address them. “It’s not going to be sufficient just to buy offsets or plant more trees,” he says, “we have to go back into the fundamentals of the operation and think about where we can prevent leaks and breaks and other systemic issues”. Thanks to new technology, we can now find leaks and mitigate them. A group of pioneering companies, many of them backed by OGCI Climate Investments, are leading the charge. And together with leading oil and gas operators, they are helping the sector cut methane for good.